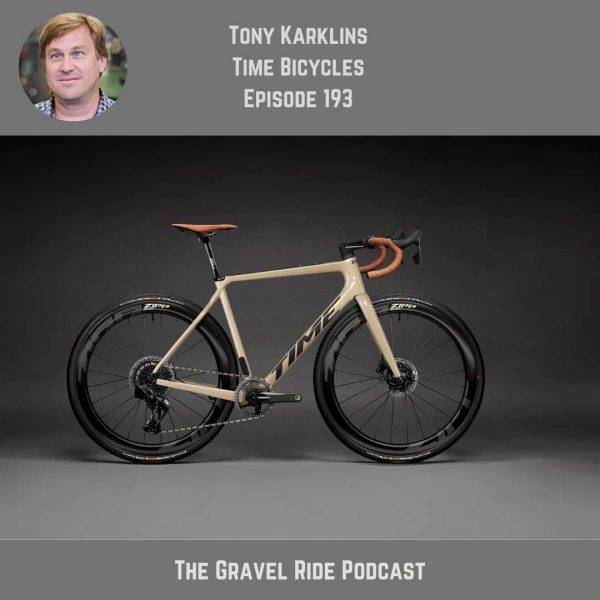

Our partner in podcasting, The Gravel Ride Podcast, sits down with Tony Karklins, the owner of Time Bicycles. We discuss Tony’s journey in the bike industry, from working in a bike shop to becoming a distributor and eventually acquiring Time Bicycles. Tony shares insights into the evolution of the bike industry, particularly the impact of carbon fiber technology. He also talks about the acquisition of Time Bicycles and the company’s focus on manufacturing and innovation. The conversation then shifts to the new gravel models introduced by Time Bicycles for 2024 and the unique features that set them apart. Tony explains the importance of staying true to the Time brand while catering to the evolving needs of the market. He also discusses the future plans for Time Bicycles, including expanding manufacturing in the United States.

Click below to Play the Podcast

Also, Gravel Cyclist’s latest review bike, the Time ADHX 45

Podcast Automatic Transcription by The Gravel Ride (please excuse all errors)

[00:00:00] – (): Craig Dalton: Tony, welcome to the show.

**** – (): Tony Karklins: Thank you very much. Thanks for inviting me. Uh,

**** – (): Craig Dalton: as, as a fan of the sport and someone who’s been around the sport from my bike shop days in college till now, I’m excited to talk about Time Bicycles. It’s such a storied brand in the industry. And having spoken to you a little bit offline, your journey to get there, I think is going to be fascinating for the listener to learn about.

**** – (): Craig Dalton: And ultimately we want to talk about the new gravel models you’ve got for 2024. Sounds great. Where do you want to start? Let’s start off just by a little bit of your background. Where are you located and how’d you get into the sport of cycling and what led to you working in the bike industry? All

**** – (): Tony Karklins: right.

**** – (): Tony Karklins: I, uh, I live in Little Rock, Arkansas. You know, Arkansas is the new hotbed of cycling globally now. So, uh, I’ve been in the bike industry here for about 40 years. I started to work in the neighborhood bike shop in the early eighties. Became a bike shop owner in the mid 80s, and I ran 2 retail stores here until 99, 2000.

[00:01:00] – (): Tony Karklins: It’s almost made it 20 years in bike retail here, and I decided that I wanted to stay in the bike industry, but I was kind of done with retail. I’d taken my turn there, and so I started traveling to the European trade shows. Looking for bike brands that were established in Europe that maybe needed help in the United States.

**** – (): Tony Karklins: Um, and did a few small distribution and agent deals with some, you know, really neat, small artists and Italian brands and kind of 1 deal led to the next. And then, uh, late 99 or early 2000. I was introduced to this brand that I had never heard of. And no 1 in America had at that time was called. And it was a tiny little, uh, BASC company that was moving out of kind of mass production bikes, and they wanted to get into high performance, and they wanted to get their brand on the Tour de France, and they wanted to see if they could produce, you know, a leading global brand, and started as a distributor for them for a couple of years.

[00:02:00] – (): Tony Karklins: It went really well, uh, and then we built it into a joint venture, and I ran that joint venture as the managing director of the Americas until 2014. So, uh, yeah. And we built Orbea in that time to, you know, leading European brand selling in the United States and a true global player. And it was a really interesting time in the bike industry because I started in it right before the carbon fiber boom happened.

**** – (): Tony Karklins: When I went to work for Orbea, premium bikes were made out of really lightweight steel. Uh, or, uh, even and we advance in a really lightweight aluminum, like Columbus Starship and some of the really cool 2 pound aluminum frames and they were light and they were fast, but they wrote like crap because they were so stiff.

[00:03:00] – (): Tony Karklins: Right? Yeah, I mean, carbon fiber comes into the forks and all of a sudden it made the aluminum bikes ride a lot better. And so, uh, watch, watch carbon fiber hit the bike industry, and it really took the industry by storm in around 2003, 2004. There was this moment where all the best bikes in the Tour de France were aluminum or titanium.

**** – (): Tony Karklins: And within 12 months, it all went carbon fiber. And really changed the bike industry a lot because the bike industry and the bike brands, all this history brands that you know of, they were born as metal shops, right? They can cut and weld and bend, but when carbon hit, everybody was like. What is this stuff?

**** – (): Tony Karklins: Where do I get it and how do I do it fast? And so I lived in this moment where I saw all that bike production all through the United States and Europe come down in the premium categories and get shipped to Asia because they could make carbon fiber. Yeah.

**** – (): Craig Dalton: I was going to ask you from an Orbea perspective, like how did they solve that problem?

**** – (): Craig Dalton: They knew they had to get into carbon fiber, the same

**** – (): Tony Karklins: thing at the same time. You know, Orbea was Orbea is they take fast, smart decisions quick. So we were right there at the very start of carbon fiber. I remember there was this moment in America where we had a warehouse full of carbon fiber before it was really.

[00:04:00] – (): Tony Karklins: Hot, like a couple of months before it was hot and then Cannondale went into bankruptcy and then something happened at light speed, but spike the cost of titanium raw material. And then like a month of fearing. I would never be able to sell this inventory for a bicycling magazine being sold out for 2 years.

**** – (): Tony Karklins: That was some of the magic that happened during that time. A lot of, uh, when carbon hit, it just, it hit hard and it changed the industry and it changed where and how bikes were made. Um, and it was a, it was a boom moment for us at Orbea, for sure. We, we, we, we went through the roof, you know, because we were there.

**** – (): Tony Karklins: One of the very first real product and real availability. Yeah. So I had a great run with, with Orbea. Um, they acquired the rest of the company from us in 2014. And then I decided that, um, I wanted to get into manufacturing because I noticed at that moment in 2014, 15 and 16, that everybody was sort of cooking in the same kitchen, you know?

[00:05:00] – (): Tony Karklins: It was, everything started to look alike again, and there was just different colors and graphics and marketing campaigns. So I said, okay, if I’m gonna stay in the bike industry, I wanna get into manufacturing.

**** – (): Craig Dalton: That seems like a big leap, right? So you a big

**** – (): Tony Karklins: leap. But you know, I, I, I, I’d been in the industry a long time, been in a lot of the factories.

**** – (): Tony Karklins: I mean, I saw it, you know? Yeah. I’m not an engineer. Um, now I almost am. But um, at that point, I just, I knew that, I knew that there was very little chance of success if you just went to Asia and did the same thing again. Yeah, I’ve seen too many people try to start their own brand, um, based on just desire of having a brand and no real tech or no real, you know, capabilities and, and they all kind of petered out the same way.

**** – (): Craig Dalton: And did you see the opportunity being, Hey, if I stand up a manufacturing facility, I’ve got enough connection in the industry that some brand may want to come to me for manufacturing. I’m thinking back to like. Frank the welder shop and you’d have,

**** – (): Tony Karklins: you know, interested in OEM business because you know, you, you do all the work and you get none of the room.

**** – (): Tony Karklins: Yeah.

[00:06:00] – (): Craig Dalton: Can’t explain to anybody what you do for a living because you can’t point to anything.

**** – (): Tony Karklins: Yeah. I was more interested in. Okay. I think the way that this can really work is if you take it from raw material all the way through to the sand. Right. Okay. Do you want all of that? Because, you know, when you have a bike made in Asia, you have it made in a carbon fiber factory and then they send it to a paint factory and then they send it to an assembly factory and then they put it into a box and they ship it into the United States.

**** – (): Tony Karklins: So you pay duties and freight and tariff and all that stuff. And then it’s sold to a distributor and then it’s sold to a retailer and then it’s sold to the consumer. And, you know, you have this, You know, no one has any real piece of the pie, you know, the only people making the money here are the shipping companies and the government, you know, let’s break that.

[00:07:00] – (): Tony Karklins: Let’s see if we can take it from raw material all the way, you know, through selling it to a dealer. Okay. And so, uh, after my time with Orbea, I went to work with a group in California that was attempting to do this, uh, with golf technology, a lot of golf production in the San Diego area. And I learned, you know, during that year that.

**** – (): Tony Karklins: Very difficult to do manufacturing in Southern California. It was, it was a great, great learning moment for it. Um, and so did not work there, but after I departed, I was able to acquire the Guru Bicycle Factory. In Montreal. Gotcha. Okay. We located in Arkansas, got some government grants and brought in some investors for this.

**** – (): Tony Karklins: And we, uh, the project there, we created this company called HIE Villa, which was going to be, you know, mass production of prepreg carbon fiber bicycles, you know, made the same way that the best bike brands were making them in Asia, but making them here.

**** – (): Craig Dalton: And when you, did you not acquire the Guru brand, you just acquired the means of manufacturing at that point?

**** – (): Craig Dalton: I just acquired the manufacturing assets. Yeah. And was that just, uh, tooling, machinery, et cetera, or were you getting

[00:08:00] – (): Tony Karklins: Messiness, cutting tables, it was everything you needed to do. Gotcha. I mean, everything, you know, and so it gave us a great, it was a great start. Uh, it was a beautiful project. We launched, you know, six Cycleworks brand, and that hit hard.

**** – (): Tony Karklins: You know, it resonated just perfectly at that moment because it truly made an America product. Um, we, we did it right. We did it well, um, beautiful project and that company got acquired by the Walton family. In one of their groups, uh, that owns, uh, the Rafa

**** – (): Craig Dalton: cycling brand and then was that acquiring the brand and the manufacturing

**** – (): Tony Karklins: facility?

**** – (): Tony Karklins: They took it all and they did that a little rock and they put it in Northwest Arkansas. And now it’s part of the, uh, the cycling empire that they’re building. Sure. And so I stayed here in Little Rock after that and looking for my next opportunity. And during the early stages of the pandemic, I learned that the Rossignol group who had recently acquired time was looking for a new owner for it.

[00:09:00] – (): Tony Karklins: And I’m like, wow, I really want that because I want, I want their factory. Cause I knew that they had the oldest and the largest scale carbon fiber bike

**** – (): Craig Dalton: factory in Europe. Can we, can we pause for a second, Tony, and just explain the history very briefly of the time brand? Cause it’s not lost on me, like how important that had been over the last 30 years, but I’d just love to hear your words and understanding of like how time fit into the bike industry.

[00:10:00] – (): Tony Karklins: Yeah. So time, uh, was established in France in 1987 and Roland Catan was the founder of it. And Roland Catan married a woman whose father was the inventor of the modern ski bike. And he owned a company called Look. Yep. Sure. And Look had just introduced a bicycle pedal that was clipless. And Roland was around this and he was kind of part of the company.

**** – (): Tony Karklins: And I guess at some point there was some family dispute that happened, because Roland believed that a clip in bicycle pedal needed to have some kind of rotation. Because if you were locked into one place, You would have ankle, knee, some kind of problems. And so, I guess the father in law didn’t like that.

**** – (): Tony Karklins: And Roland left look, went across the street and opened time. Amazing. With a clipless pedal that had rotation.

**** – (): Craig Dalton: This is filling in so many gaps for me. As I mentioned offline, I had a friend who was like a die hard time pedal fan. And like the ski binding technology, I’m now all visualizing it in my head.

[00:11:00] – (): Tony Karklins: And so I don’t know how, I don’t know how Roland’s wife made this all work with the family. They split and they made it together. Um, and you know, Time, you know, was a very fast moving brand globally the second he did it. It was styled perfectly. Everybody believed in the rotation. They were off to the races.

**** – (): Tony Karklins: Um, then somewhere in the late eighties to maybe 92, 93, Roland became friends with some of the people that had started TVT carbon fiber and TVT was, you know, uh, French company. That had done some of the very first, you know, carbon tube, aluminum lug bikes, they were briefly in the tour, but the technology wasn’t really stable enough yet to really have true tour riders on it.

**** – (): Tony Karklins: But you, I think you saw maybe some of the Greg Lamont years, he might be on a special carbon fiber bike with some sponsors name on it. That was a TVT thing. So the time people got involved with him. Um, and they opened up a project to make a carbon fiber fork because they saw the problem in the bike industry of all these lightweight aluminum bikes using steel forks, or sometimes even aluminum forks, which were super jarring.

[00:12:00] – (): Tony Karklins: Yeah. And they believed that they could, they could make a better riding aluminum bike by doing a carbon fork. So Mario Cipollini, Marco Pantani, anybody of who’s who in that, you know, in that era, whatever bike brand they were riding, it had a Time fork on it, and from what I’ve been told, uh, they were making about 100, 000 carbon fiber forks here.

[00:13:00] – (): Tony Karklins: I mean, they, they were, they were the player there. Then, of course, Look got into the fork business as well. Those 2 really kind of hit it, you know. So time then moved into bicycle manufacturing in the late 90s. They want to do a full carbon fiber bike. Um, and then in the early 2000s, they signed with this little team called Quickstep and we had writers like Tom Boonen and Paolo Bettini, uh, you know, and they won the Olympics and they won the world championships and they won Paris Roubaix and they were just, they were killing it in 2004, five and six, I mean, they were, they were the, you know, pinnacle of technology really being made in Europe when everybody else had just left for China, they were killing it.

**** – (): Tony Karklins: Um, and then. I guess from what I’ve been told, the Pro Tour got really expensive when the big American brands came in. You know, when you saw Specialized come in and take over Quickstep, and Cannondale was in there first, I think, Giant got in there, uh, Trek obviously got in there, and so Time became a brand that, you know, truly couldn’t afford the Tour de France anymore.

**** – (): Tony Karklins: And so, uh, they Kept developing products, they believed in their resin transfer molding technology. They believe in European manufacturing, but, you know, they started to kind of hit harder times, maybe in 2012, 13, 14, and then Roland passed away on a bike ride. In 2000, late 2015, early 2016. Oh, man.

[00:14:00] – (): Craig Dalton: And did they ever, did they ever diversify into mountain bike products or did they always stay focused on the road sport?

**** – (): Craig Dalton: No,

**** – (): Tony Karklins: there’s, you know, we, we have all the historical stuff and, you know, they did a couple little things and they made their own wheels for one model, but they didn’t really ever get in the wheel business. I’ve got a few time carbon fiber handlebars. I don’t believe that a real mountain bike frame was ever truly produced by them, but he was pretty true to the cause.

**** – (): Tony Karklins: I mean, he, he was a road cyclist. He was a drop bar cyclist. He, um, he, he, he protected his brand really well. Yeah. Yeah. He, he didn’t, he didn’t go with, you know, the, the, the trend of the week, like some of the bike companies do.

**** – (): Craig Dalton: And then did the Rossignol group, uh, purchase it after his passing

**** – (): Tony Karklins: then? They purchased it, you know, so he passed away.

[00:15:00] – (): Tony Karklins: Company was in shambles because he was the race car driver of the company. Right. Yeah. And, and so big problems there, but Rossignol stepped in. Um, they. They did an acquisition of everything, they reinvested in the company, um, they built out both the France factory and the sub factory that’s in Slovakia.

**** – (): Tony Karklins: Um, and they were really building it for big growth. And I, I believe their plan was to, to put, um, they, they bought a few other bike brands as well and to inject those brands into their ski dealerships for summer business in Europe. I think it was their master plan.

**** – (): Craig Dalton: The plan that many a bike shop owner, many a bike brand has theorized over the years will work perfectly.

**** – (): Tony Karklins: It makes sense. But at the end of the day, you know, a consumer purchasing a 10, 000 bike doesn’t want to buy from the ski shop. Yeah. I know. Yeah, nothing against the ski shops, but he wants, he wants to buy it from a passionate, you know, cycling store. So that didn’t work so well. And then the pandemic hit, and when the pandemic hit, that’s when we were told, Hey, good time.

**** – (): Tony Karklins: Rosalind was looking for a new owner from time. And I

[00:16:00] – (): Craig Dalton: interrupted you right when you were saying what really attracted you to the opportunity was the fact that there was a factory involved.

**** – (): Tony Karklins: And that’s how we got it from Roil because we were the people that wanted the factory. I think there were a lot of people that wanted the time brand, right?

**** – (): Tony Karklins: Sure. Because there’s a playbook. You take a great brand like that, a Halo European brand, you go to Asia, you build a new bike line, boom, you’re done. And Ros, I don’t think, wanted that to happen. You know, it’s proud French brand. There are a lot of people working in factories. Um, they wanted, they wanted somebody to come in and take over the factory.

**** – (): Tony Karklins: I had just come through this project at Allied and lived in a prepreg factory. So I’m like, I want that factory, you know? Yeah.

**** – (): Craig Dalton: And you were mentioning offline, some of the nuances in the approach prepreg versus another way of manufacturing that attracted you to the

**** – (): Tony Karklins: time process. I knew what their tech was, but I had never been in their building previously.

[00:17:00] – (): Tony Karklins: And, and I knew the quality that was coming out of that. And so when, when we were able to acquire that, you know, at the same time, SRAM bought the pedal and shoe business. So we actually broke time. Into two pieces. Okay. So that was a perfect fit for SRAM to take that and then we didn’t have to be in the pedal business.

**** – (): Tony Karklins: Did

**** – (): Craig Dalton: that just sort of happen to work out timing wise that I imagine they wanted to sell the whole thing in one fell swoop.

**** – (): Tony Karklins: I think they wanted to sell the whole thing in one fell swoop, but it’s hard to do that because those two businesses are totally different, totally different factory, totally different customers, totally different rules.

**** – (): Tony Karklins: And so when SRAM stepped in with interest in that, it was perfect. And that’s when it all kind of came together. And, uh, you know, it was a strange time because when we bought it in the pandemic, we couldn’t even go to the factory for a visit. Because this is what Americans travel into Europe. We were on lockdown.

[00:18:00] – (): Tony Karklins: Yeah. So a lot of faith in there. And luckily we got a good investment group behind this that also believed in, in us, in the vision of what we wanted to do with time. Uh, and we pulled it off. So we bought it because we wanted that factory. We wanted that technology. You know, what, what Roland spent, you know, 25 years developing in that factory is resin transfer molding and lost wax cores.

**** – (): Tony Karklins: And that is the way that aerospace and automotive carbon fiber products are made. You know, the bike industry is prepreg. Prepreg is a very interesting way to make products. And there’s some neat things you can do with prepreg. But automotive and aerospace would never use prepreg. Because resin transfer molding gives you complete control of the structure.

[00:19:00] – (): Tony Karklins: You end up with a, with a structure that has zero voids in it. It’s cosmetically perfect. And that you can blend whatever you want to into the carbon fiber sleeves because they’re not impregnated. And so, this one factory that they had built in Slovakia initially as a fork factory had built its way up to being the largest carbon fiber bike factory in Europe.

**** – (): Tony Karklins: And with the technology that Was above and beyond what anybody else in the world was doing. When

**** – (): Craig Dalton: you talk about that, and I’m sure it’s difficult to express it in layman’s terms, but when you think about the different design opportunities and possibilities with prepreg versus this type of carbon manufacturing, what type of opportunities for performance, as it translates to riders, does this technology lend itself to?

**** – (): Tony Karklins: You know, the biggest difference in resin transfer molding, Is it’s not, it’s not bladder mold. There’s no internal pressure there that is squeezing all those layers of carbon fiber into one structure. So, in resin transfer molding, we start with the wax core. It is, you know, an exact interior core to the structure.

[00:20:00] – (): Tony Karklins: And then we wrap the carbon fiber sleeves over those doors. We set them in the tools. When, and when we close the tool, you have steel surface on the outside, hard wax surface on the inside. So two hard surfaces, and then you inject the resin and the hardener through the tool at the same time under high pressure.

**** – (): Tony Karklins: And when you do that, the resin fills 100 percent of all available space between the two hard surfaces. So you can’t have any leaks. That’s why airplane wings are resin transfer molded, because you can’t have a void in an airplane wing. Because a

**** – (): Craig Dalton: void is a, is a weaker part of the part, if a

**** – (): Tony Karklins: void exists. A void is a bubble, it’s a fold, it’s a wrinkle, it’s a drip.

[00:21:00] – (): Tony Karklins: It’s, you know, because when you’re dealing with prepreg, you have this hard tool on the outside. You have, A bladder on the inside, and then you have all these sticky layers, somebody’s hand put together, kind of like, almost like paper mache in some ways, right? And each one of those is a sticky, challenging layer.

**** – (): Tony Karklins: These will go on just right, right? And then you put that into the tool, and you blast this pressure on the inside, and it just squeezes the heck out of everything. And that’s the structure you’re left with. But resin transfer molding, hard tool on the inside, hard on the outside, and a flow through of the resin that makes it a perfect structure.

**** – (): Tony Karklins: And so when you have that, you have a product that is a stronger and more durable product for sure. Less chance of anything happening to the structure for sure. Also cosmetically perfect. So now you can actually show fibers, which you don’t see on carbon fiber bikes anymore, because prepreg structures are ugly.

[00:22:00] – (): Tony Karklins: So you have to paint them, make them look nice. But on this, it comes out perfect. And even the inside of the structure, the inside of our bikes is as cosmetically perfect as the outside because it can only be that. Yeah. And then in these braids, you know, a lot of these things have 244 different, you know, threads through we can.

**** – (): Tony Karklins: blend in any modulus that we want. We can mix in fibers like Dyneema. We can mix in Vectran fibers. We, we have unlimited recipe of what we could do for the actual sleeves

**** – (): Craig Dalton: themselves. And what, what are those additional elements? What are the benefits of those additional

**** – (): Tony Karklins: elements? Everybody’s familiar with the different moduluses, right?

**** – (): Tony Karklins: You can take out weight, you can add stiffness. You know, the one that we’ve had the most fun with the last two years is bringing Dyneema into it. Dyneema has got kind of a wonder material that really came out of the sailing industry. It’s a polypropylene fiber that’s lighter than carbon fiber, which you can’t destroy.

[00:23:00] – (): Tony Karklins: So we can weave this into critical areas where there could be catastrophic failure. And this will keep that structure from ever breaking. And so we brought that in a lot on our 1st gravel bike. We introduced that indoor

**** – (): Craig Dalton: structure. Yeah, I was going to say that seems like a natural

**** – (): Tony Karklins: thing. We’re using more and more and more with it.

**** – (): Tony Karklins: And you can’t use too much with it because if you use. Two, if your ratio of Dyneema to the carbon fiber is too high, the bike doesn’t ride right. Dyneema doesn’t have the riding characteristics of a high modulus carbon fiber. But when you put it in small doses in strategic places, you’ve made a stronger and safer problem.

**** – (): Craig Dalton: Got it. Now, I appreciate this detour into the tech because we were going to come back around to it in the gravel bike, but I think it sets the stage really nicely. So if we’re going back chronologically. 2020, 2021, it seems like you’ve acquired the, the, the brand, the facility were models continuing to be pushed out at that point.

**** – (): Craig Dalton: And then how, when did you sort of reintroduce what I imagine to be your new vision for time bicycles out there in the world?

[00:24:00] – (): Tony Karklins: You know, it, it played out differently than we thought because when we bought the company, our plan was we were going to take it to ground and we were going to redo everything and we were going to relaunch it perfectly and we bought it in that moment in the pandemic where we were all going to die, you know, there was this moment.

**** – (): Tony Karklins: It was doom and gloom. And then a couple of months later, everybody decided to go buy a bike. Yeah.

**** – (): Craig Dalton: We’re not, we’re not dead. So we might as well go ride a bike.

**** – (): Tony Karklins: Yeah, we’re not dead. So let’s go buy a new bike. And so our plan was kind of spoiled because we were one of the only operational factories in Europe.

**** – (): Tony Karklins: Everybody needed everything from us. And I’m like, no, we’re going to be redoing all this stuff. They’re like, no, we need bikes now. So we turned it on hard. You know, we turned that factory on harder than it had ever

**** – (): been

**** – (): Craig Dalton: turned on. And were you kicking out road bikes at that point,

**** – (): Tony Karklins: presumably? We were kicking out road bikes like crazy.

[00:25:00] – (): Tony Karklins: We were trying to get to gravel, but we had just tons and tons and tons of orders for road bikes because, you know, you couldn’t get them. They were stuck in Asia. People were sold out. Yeah. You know, and you know, we’re a factory that we make them every single day, you know? So the first 18 months of us owning this company, it was like we were trying to repair the plane mid flight.

**** – (): Tony Karklins: You know, we were just going crazy. You know, we’re trying to get to new. Because Rossignol didn’t really push new because they were in the selling phase. Right. So you’re not going to invest in products like that. And so we had slightly dated product and we needed as much of it as possible right now for sales while we’re redeveloping.

**** – (): Tony Karklins: So just now, you know, in 2024, we’re back to our plan of, of key new model introductions,

**** – (): Craig Dalton: you know. Yeah. You know, during that timeframe with everything running so fast, it sounds like you wouldn’t have even had time to rethink market positioning the brand. It was more people love time. It’s a storied brand as we’ve just talked about, and people are going to buy the product.

**** – (): Craig Dalton: The

[00:26:00] – (): Tony Karklins: second we bought it, man, the love just kind of flowed in through emails, you know, everybody’s like, Oh God, thank God, you know, cycling people have the time brand, you know, and, and yeah, the love for the time brand is amazing. I can’t tell you how many people have sent an email with a picture of their Time VRX, VXRS, Paolo Bettini edition to say, I own a hundred bikes and this is my all time favorite.

**** – (): Tony Karklins: You know, people love it. I mean, Roland did a great job building a really beautiful, he really, he, he always. Did the right thing. Yeah. Always took the high road. You know, not a lot of people in the bike industry can really say that.

**** – (): Craig Dalton: For sure. You mentioned Roland’s love of the sport of road cycling, and it doesn’t sound like prior to you much, if any, emphasis was put on the gravel market.

**** – (): Craig Dalton: When you decided to move in, or correct me if I’m wrong, certainly.

[00:27:00] – (): Tony Karklins: Well, there were some weird things in there. Like one of the things, when we did the acquisition and we got the trademark, Roland owns the global trademark for all. Okay, we were looking at that. Oh, my God. What was he going to do with that?

**** – (): Tony Karklins: You know, he saw something, you know, maybe he was maybe had a pedal plan for it. But, you know, he, you know, he was pretty deep in the Belgian site. Okay. And so he, he was, he was working on something for sure.

**** – (): Craig Dalton: Gotcha. You weren’t handed any gravel models, so it took you, took you to what, 2022 to introduce the first, uh, ADHX?

**** – (): Tony Karklins: Yeah, we did. We introduced that, um, midway through 2022.

**** – (): Craig Dalton: Now I’m curious, like obviously you had your imprints on that model with you alongside your designers. How did you envision the gravel market at that point? Times the, the time, the people who are appreciating the time brands vision for what a time gravel bike would look like.

[00:28:00] – (): Tony Karklins: Well, that was our first rule with the ADHX is we wanted to make a bike that would appeal to time. Right. We weren’t going to go out and make some bike that had frays on forks everywhere and for camping on it. That’s not time, right? You need to go buy a Surly if you’re going to do that. We wanted to do an all road bike.

**** – (): Tony Karklins: For a time and we wanted to also make sure that it worked with all road drive trains. Because we want to be a multi surface road bike. Gotcha. We call it fast gravel. Um, and and we introduced that before a lot of these wide drive train 1 by systems really became legitimized and, you know, our requirement is let’s get biggest tire possible in here.

**** – (): Tony Karklins: It will still take 52 chain ring. You know? Yeah. And we’ll not have an obscenely long chainstay. So we’ll ride like a road bike, but we’ll allow you to do multi surface. Yeah.

[00:29:00] – (): Craig Dalton: I’ve had this conversation before where it’s very interesting when you talk about constraints and what you’re able to do. And as you’re articulating the desire to have a 50 tooth chainring in there and ride a two by drivetrain and a road specific drivetrain, it’s understandable where you end up spec wise.

**** – (): Craig Dalton: Yeah. I

**** – (): Tony Karklins: mean, so that, that’s, those are the limitations we put on it. And so then we launched it into the market. You know, and at that moment, anything, anybody launched into the market was going to do well because the market was just consuming all by itself. But quickly, we learned that nobody wanted our ADHX with a one by drive train.

**** – (): Tony Karklins: Everybody who was buying, because we made, we, we took an assumption that 50, 50, one by two by, you know, and it was 99 percent and 1 percent was the reality of after six months of this. So everybody, they were buying pure road groups and they were running. You know, 35, maybe 38 C tires.

**** – (): Craig Dalton: Yeah. It’s interesting when you think about that 2022 timeframe, because I do think the, the consumer base had started to really.

[00:30:00] – (): Craig Dalton: Sort of pick a camp if you will. And they were picking either I want a fast gravel bike or I want something more on the adventure side. And there were distinct camps starting to emerge even back then.

**** – (): Tony Karklins: Yeah, there were. And, uh, you know, so we got a lot of feedback maybe nine months after launch, but we can’t get this 42 tire and everybody racing on unbound this year is running a 42.

**** – (): Tony Karklins: And then, you know, we were also at that moment where the interior rim widths were changing like crazy. Yeah, so even if you were putting a 38 seat tire on there, but this new wheel coming out from head has a 26 internal measurement. It was measuring a 42, you know, so we ran into that fun, but everybody else ran into that fun at the same time.

[00:31:00] – (): Tony Karklins: Yeah. So we decided that we would open the next project to do a wider. You know, tire version of the ADHX, um, because we thought that was truly where the market was moving to. And what we learned in all of that is it all just comes down to the drivetrain. And the second we launched the ADHX45 and we explained it was built for wide drivetrains and it was built for, you know, it won’t take Ultegra, Dura Ace, Campagnolo drivetrains on there.

**** – (): Tony Karklins: That we had this boom of sales in our existing ADHX because all of a sudden people really understood. Yeah, this is this is as much of a multi surface bike as I can have and it’d be a road bike. This is really a pure gravel, right? And so for now, it’s crystal clear. We didn’t really expect that to happen.

**** – (): Tony Karklins: We assume the 45 was what everybody was going to want, but now it’s crystallized for us where there are three for us. There’s pure road. There is multi surface pass. Yeah. And there is. You know, I don’t want to call it pure gravel, but wider tire

[00:32:00] – (): Craig Dalton: gravel. Yeah, it’s a, it’s a really interesting force and forcing function.

**** – (): Craig Dalton: Cause I think a lot of consumers develop a love and appreciation for a particular brand. And then, so they’re in the time family, they’re in the time world, and then they’re looking at your two models and they’re asking themselves, what type of gravel rider am I? Where, where do I live? What type of terrain am I on?

**** – (): Craig Dalton: And which one of these two models fits their riding style and ambitions.

**** – (): Tony Karklins: What I think we’ve learned is. It’s more important around the drivetrain than it really is around three or four millimeter width change on the top. That’s what the customer seems to really care about.

**** – (): Craig Dalton: Interesting. So on the, on the, the ADHX45, will that still run a 2x?

[00:33:00] – (): Tony Karklins: Yeah, it’ll run a 2x, but you have to use a wide version of it. Okay. Yeah. So you’re using these, these gear ratios that true road cyclists Don’t really, they still want their 52 ring on there, right? Yeah. And when you move into the a H 45, you gotta deal with all, all the new systems from Shram and the new ones from the G Rx system.

**** – (): Tony Karklins: And it, it does, it does really seem to be that the 45 falls more to the MTB crowd and the A DHX falls more to the road cyclist. It just wants to do a little bit of ground. Yeah. As you and then, and then in Europe they use the A DHX. As the fat road tire. Okay.

**** – (): Craig Dalton: And what do you, does it ride sort of as if it say you have road tires on their 32s or 35s?

**** – (): Craig Dalton: Is it ride like an endurance road bike? Would you, would you suggest? That’s

**** – (): Tony Karklins: where a lot of people have kind of put it. Yeah. You know, cause you can, you can build out, you know, with those Victoria 34 C tires and nice carbon wheels, you can have a, you know, 14 and a half pound 34 seat tire road bike. It’s just super fun to ride.

[00:34:00] – (): Craig Dalton: Super fun to ride. Yeah. Yeah. Yeah. I was just out with a buddy I hadn’t seen in a while. And so he was like hardcore roadie and saw him rolled up on some 38 Cs, nice carbon wheels. And he was like, man, this bike is, he’s like, it’s a revelation. He’s like, I’ve never been happier road riding than I have been on these 38 Cs.

**** – (): Craig Dalton: Yeah, I love it. Super interesting. As you, you know, you had the the 80 HX out there in the market. Obviously, you were getting some feedback from riders that led to the tire and drive train decisions on the 45. Were there any other elements of the frame design that taking the opportunity to think? Hey, we’re now getting 45s in there.

**** – (): Craig Dalton: People are going to take this on gnarlier terrain. Do we need to do anything different? Or was it really about upsizing and, you know, configuring the drive

**** – (): Tony Karklins: train? You know, when there were some people that were pushing us for adventure bikes and stuff, but it’s just, we’re, we’re doing our best to stay true to time.

[00:35:00] – (): Tony Karklins: We’re not an adventure bike company, we’re a high performance carbon fiber bike company. We want to, we want to keep it that way. So I think, I think the 45, at least. What we see of today’s gravel market is as far as we need to go, you know, because there are other things at the time brand needs to do. We know we have to get back into the aero road bike development and we have to get back into endurance road development.

**** – (): Tony Karklins: We’ve got other projects there. So I think that, you know, while we’ll continue to evolve the ADA checks family, I think we sort of have our two models

**** – (): Craig Dalton: in there. Yeah. When you think about it, you mentioned sort of unbound. When you think about a competitive race bike, is there anything that The ADH X45 has that doesn’t put it as a gravel race bike, other than the choice of drivetrain that you’re, you have to

**** – (): Tony Karklins: make because it was, it was really built for that type of application.

**** – (): Tony Karklins: Yeah, it a go fast. You know, wide tire ground. Yeah. You know, it’s, it’s a race bike. I mean, we, we, we did some really tight tolerances on there. The things we had to do to get the chain stays, you know, in the seat too. And just, just to the point where they’d be right on the edge of giving the proper amount of clearance.

[00:36:00] – (): Tony Karklins: And, and, and truly be a high performance ride. We, we couldn’t have done it any tighter than we did. Yeah.

**** – (): Craig Dalton: Yeah. And when you think about the ideal rider for these types of bikes, um, are you, you know, are the head tubes taller or are they, or are they still sort of real Euro race style

**** – (): Tony Karklins: geometry? We are upper middle there on this particular family when we, well, when we bought time, there was no integrated front ends at all.

**** – (): Tony Karklins: So we had to, the first project we did was to do, to bring integration in when we did that to all of our existing product line, we increased that head to height just a bit more for the, for the mature American market.

**** – (): Craig Dalton: And when, with integration, you’re talking about

**** – (): Tony Karklins: specialized Roubaix, we didn’t, we didn’t go there, but we brought it to a point because I, I hate premium bikes with three or four spacers in there.

[00:37:00] – (): Tony Karklins: Or, or an upstem. Yeah. So we built it, you know, we engineered it to sell and be looked at.

**** – (): Craig Dalton: Okay. And with that integration, you’re referring to putting the cables inside the bar and through the headset and all that stuff. We got a moment to

**** – (): Tony Karklins: tweak all the hit tube heights when we did that. Yeah. And so we, we, we took, we took benefit.

**** – (): Tony Karklins: We cleaned that. Got it. Because, you know, traditionally time Short head to bike. I mean, it was the, a lot of the design was led by the racers who all want these head tubes that are this tall. Yeah. You know, nobody who’s actually buying a bike and ever ride, you know,

**** – (): Craig Dalton: exactly. Um, what, what’s sort of next for time and gravel this year?

**** – (): Craig Dalton: I imagine, you know, there’s still a lot of people who haven’t gotten in front of a time. Gravel bike. How do people find

**** – (): Tony Karklins: them for time right now is, um, our expansion into manufacturing in the United States. Okay. That’s our next thing. So we announced, uh, middle of last year that we acquired a facility in South Carolina and it’s in Spartanburg County.

**** – (): Craig Dalton: Was it outside the bike industry? Something doing carbon fiber in another field?

[00:38:00] – (): Tony Karklins: No. Um, but it is inside the bubble that BMW built in North America and BM W’s carbon fiber technology is exactly the same as times. Got it. So it’s resin transfer molding. So in this one little region of South Carolina, they have the entire global supply chain specific to exactly what time does.

**** – (): Tony Karklins: Amazing. So we acquired a factory there in this little town called Landrum. It’s 140, 000 square foot facility on 30 acres, right at the base of the Blue Ridge Mountains. Really cool area. Uh, about, about 30, 45 minutes from Nashville, North Carolina. And we are. Um, throughout 2024, moving process by process over, so we’ll have a second factory here to support the United States.

[00:39:00] – (): Tony Karklins: And at the same time, as we’re installing our processes into that factory, we’re getting a lot of assistance from, um, the state of South Carolina and the University of Clemson, and a lot of the, um, automotive, Development tools that were put into place inside of BMW. They do things with resin transfer molding that were light years beyond what Roland ever thought about when he was building his factories in France and Slovakia.

**** – (): Tony Karklins: And so we’ve been for the last six months doing proof of concept manufacturing there about, um, high pressure resin transfer molding. We’re similar technology to what we do in our factories now. But under three to five times pressure, and that has the potential to really, uh, has the potential to revolutionize bicycle manufacturing, but certainly advance our product to a point where beyond what we ever thought possible.

[00:40:00] – (): Tony Karklins: When you, when you are able to do resin transfer molding at 35, 45, 50 bar, that is incredibly high pressure. It’s going to make a A structure that is thinner, lighter, and stronger, and also more beautiful than anybody’s ever been able to pull out of a carbon fiber tool. So we are fully focused on that development and deploying that technology in our new South Carolina factory.

**** – (): Tony Karklins: By the end of

**** – (): Craig Dalton: this year, that’s so exciting to bring back more manufacturing in the United States. And as we heard,

**** – (): Tony Karklins: that’s the real thing, you know, because the automobile industry invested a lot in resin transfer from BMW, McLaren, Aston Martin, Lexus. Audi, I mean, resin transfer molding used in all those brands significantly.

[00:41:00] – (): Tony Karklins: Polestar, Volvo. And to take benefit of what they’ve done there and apply it to bike under the Time brand name and being true to, you know, what Roland Katana actually wanted to build out of Time. That’s, that’s our special project that we’re really excited about. I think that I’m a few months away from inviting people such as yourself into the kitchen over there so you can see firsthand what what’s actually about that.

**** – (): Craig Dalton: I love it. Book me a date. Maybe in July. My sister just moved to Asheville. So I’m planning a trip over there at some point

**** – (): Tony Karklins: 3045. I

**** – (): Craig Dalton: love it. I love it. I love this journey. You’ve taken us on in this conversation. Love the time brand. The story very much lands with me. Just the sort of. Race perspective of the bicycles and the expansion of the ADHX to the ADX45 just to give riders kind of what they’re looking for in terms of the versatility.

**** – (): Craig Dalton: In the time models. So, um, yeah, super appreciate it. And for customers looking to get in touch with the brand or get, get a foot over one of these, what’s the best way for riders to get in front of a time bicycle? You know,

[00:42:00] – (): Tony Karklins: we, our website and the team that we have supporting all lines of communication through that social media.

**** – (): Tony Karklins: We’re very easy. Okay. I mean, ping us ping us on Facebook, Instagram, through our website, we have a team here ready to help. And

**** – (): Craig Dalton: are you selling direct to consumer at this

**** – (): Tony Karklins: point? We sell every way possible. We sell direct to consumer and we’ve got around 150 retailers in the United States. Uh, we’ve got distributors in 18 countries around the world.

**** – (): Tony Karklins: Um, so yeah, we’re, we’re pretty much available in all key markets.

**** – (): Craig Dalton: Amazing. Thanks again for the time, Tony.

**** – (): Tony Karklins: My pleasure.

Until next time here’s to finding some dirt under your wheels.